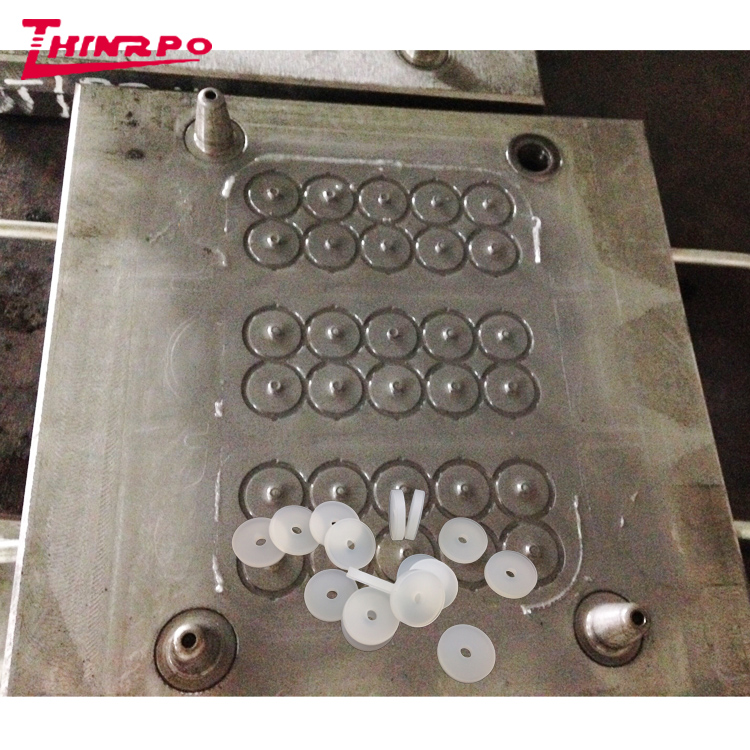

Silicone Rubber Compression Sanitary Seal Mold

Silicone rubber sealing parts have good characteristics such as wide temperature adaptability, sealing, insulation, dielectric and environmental protection.

1. Non-toxic, odorless, high transparency, no yellowing;

2. Soft, good elasticity, kink resistance and no deformation;

3. No cracking, long service life, cold resistance and high-temperature resistance;

4. Has higher tear strength and superior electrical properties;

5. High transparency, odorless, no yellowing, no frosting, etc., especially to solve the problem of black hose frosting and fading of blue products, soft, high tear resistance, high insulation, wear resistance, high-temperature resistance , flame retardant, anti-aging, environmental protection, tensile type, stable performance and other advantages.

Silicone rubber compression sanitary seal mold

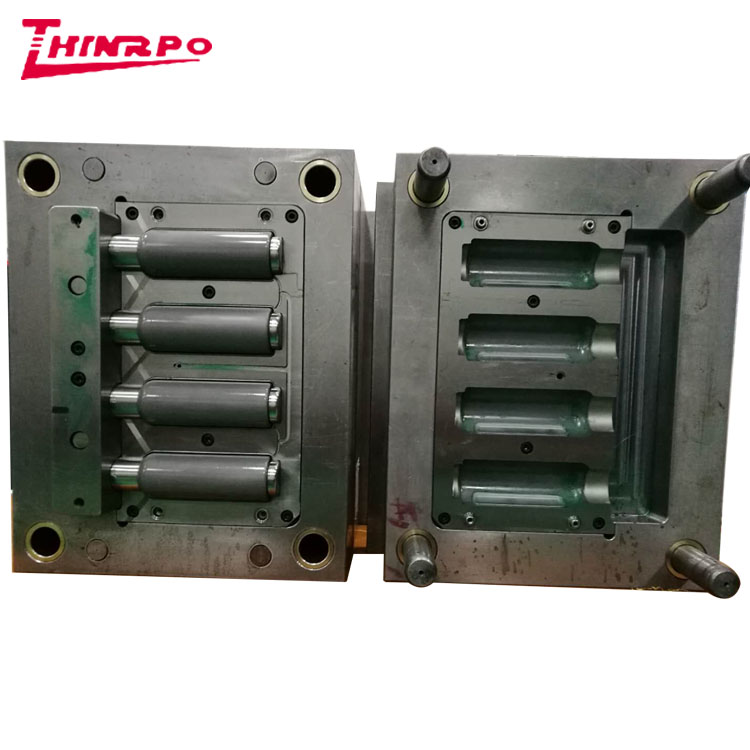

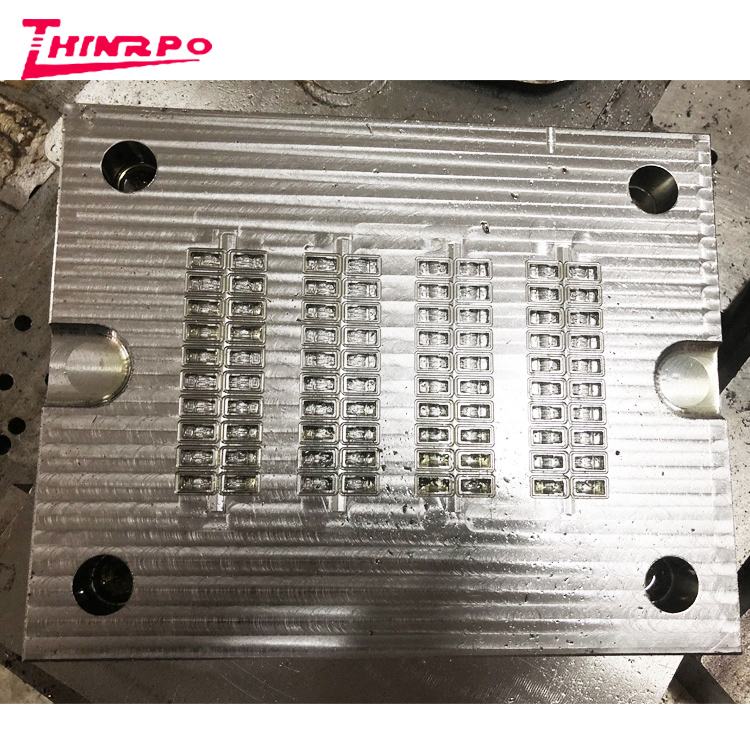

Silicone Rubber Compression mold also known as compression molding, compression moulding, rubber mould, silicone rubber mold, rubber compression mold etc. Compression mold is to first put powder, granular or fibrous plastics into the mold cavity at the molding temperature, and then close the mold and pressurize it to shape and solidify. Compression molding Can be used for thermosetting plastics, thermoplastics and rubber materials.

Silicone rubber O-ring also known as gasket, grommet, washer, seal and sealing part is a ring-shaped product made of silicone rubber (food grade silicone, medical grade silicone, NR, NBR, EPDM, CR, IIR, FKM etc). The main constituent material of general silicone rubber O-rings is VMQ-methyl vinyl silicone rubber.

Rubber O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable and have simple mounting requirements.

Rubber Gaskets come in many different designs based on industrial usage, budget, chemical contact and physical parameters.

Features:

Silicone rubber sealing parts have good characteristics such as wide temperature adaptability, sealing, insulation, dielectric and environmental protection.

1. Non-toxic, odorless, high transparency, no yellowing;

2. Soft, good elasticity, kink resistance and no deformation;

3. No cracking, long service life, cold resistance and high temperature resistance;

4. Has higher tear strength and superior electrical properties;

5. High transparency, odorless, no yellowing, no frosting, etc., especially to solve the problem of black hose frosting and fading of blue products, soft, high tear resistance, high insulation, wear resistance, high temperature resistance , flame retardant, anti-aging, environmental protection, tensile type, stable performance and other advantages.

Application:

Rubber seal are mainly used as structural parts, connecting parts, protective parts and electrical insulating parts. Widely used in industry, agriculture, transportation, electrical, chemical, construction, machinery and other fields. Due to the reliable quality of molded products, they have also been used in weapons, aircraft, missiles, and satellites.

Advantages:

(1) The loss of raw materials is small and will not cause too much loss (usually 2% to 5% of the product quality).

(2) The internal stress of the product is very low, and the warpage deformation is also small, and the mechanical properties are relatively stable.

(3) The wear of the mold cavity is very small, and the maintenance cost of the mold is low.

(4) The cost of molding equipment is low, the mold structure is relatively simple, and the manufacturing cost is usually lower than that of injection molds or transfer molding molds.

(5) The shrinkage rate of the product is small and the repeatability is good.

(6) A mold with a large number of mold cavities can be placed on a given template, and the productivity is high.

(7) It can adapt to automatic feeding and automatic removal of products.

(8) High production efficiency, easy to achieve specialized and automated production.

(9) The product has high dimensional accuracy and good repeatability.

(10) The surface is smooth and no secondary modification is required.

(11) Products with complex structures can be formed at one time.

(12) Mass production, relatively low price.