Mold Development

Mold structure of silicone rubber products and other auxiliary processes

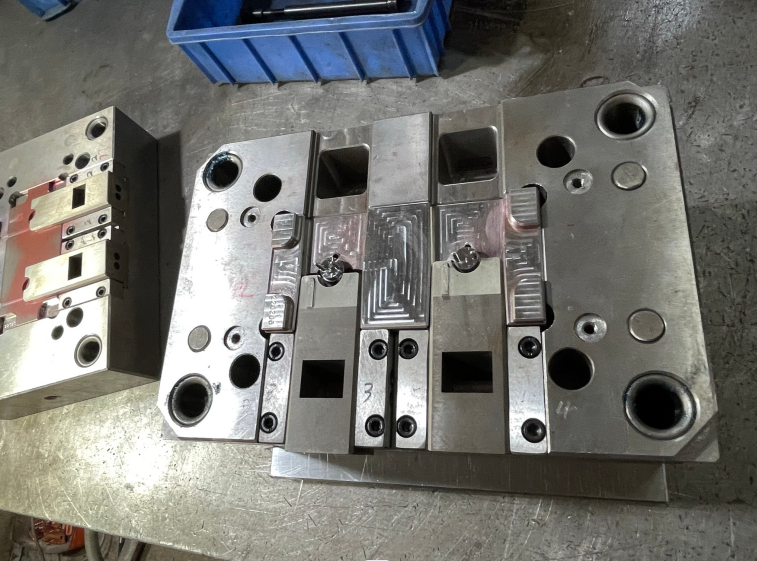

Mold structure of silicone rubber products

The upper limit of mold thickness, tentatively set at 250mm, can be up to 500X500 in size, and the product can be up to 400X400 in the mold area.The structure is generally divided into upper die, lower die, bottom plate, top plate, ejector rod, die core, hinge and other auxiliary parts.In the design of silicone products, we should pay attention to the characteristics of its mold and production process.

A. Demoulding: the demoulding of silicone products can be directly strong demoulding.To design the size of the defects of strong product requirements mainly is to maximize mold core and mold release convergent place than the circumference of the smallest, 55 ° for the following products can do 2-3 times, forced demoulding of the parts can't exist fissure and opening Angle.Due to the requirements of vulcanization at 180 degrees Celsius temperature, the work of the mold in addition to the upper and lower parts of the mold itself, almost all manual.Therefore, in the design of parts should consider the convenience of fast.So as not to affect the vulcanization quality and production efficiency of parts due to too long demoulding time.Because the demolding mode of silicone is mainly manual and the movement stroke of its top plate is also very small, there is no inclined top between the silicone mold and the plastic mold.Generally, core pulling is not set.

B. Die core fixation: Unlike plastic molds, the core of the silicone mold is usually removed along with the product parts when the mold is opened.So in the core of the fixed and accurate positioning of the plastic mold is difficult to deal with, the core of the steel requirements.In general, the core will be done together, a fixed all the core.Or the mold core through the auxiliary appliances, so that it can be quickly positioned.Because there is a lot of pressure in the closing process, so to prevent the core movement.

C. Core pulling: generally, it cannot be automatically moved, but it can be strongly removed. Core pulling is only used for small size structure.The setting of the core pulling is similar to that of the plastic mold, but it is taken out manually when the mold is opened.In addition, core pulling takes up a large space in the mold, which is not only complicated to process in one more mold, but also has a low utilization rate of the mold space.So as much as possible without core pulling.

D. Shape: when the surface of the silicone product is intact, the toughness is very high, but once there are cracks, the cracks will expand rapidly under the action of external forces.In other words, silicone products are very sensitive to cracks.In view of these problems, in the design of silicone parts should pay attention to: all positions can not have sharp Angle, so as to avoid stress concentration crack.The opening R Angle cannot be less than 0.5.

E. Selvage: the main function of selvage is to accommodate excess rubber materials;Facilitate mold exhaust;Easy to trim flash.Self-demultipleting generally by A thin edge and a corresponding strong tear edge at the parting surface of a part.The thickness of the thin part is generally 0.1~0.2, the thickness of the torn part is generally 0.8, and the width is generally 1~2MM.

F. Embedded parts: various embedded parts can be installed in the silicone products, but several problems should be noted: first, the surface of embedded parts should be pre-treated.Mainly surface vulcanization or surface activation.Otherwise, it will be difficult to firmly connect the embedded parts and the glue parts.Second, the fixing and positioning of the insert can be fixed in one direction in the vertical direction, but other directions must be fixed comprehensively.Avoid moving inserts during full die.Third, the thickness of glue around the insert.For parts that are fully coated (all surfaces are coated and therefore cannot be positioned), the edges of the inserts should be at least 0.5mm thick.For positioned inserts, the thickness of the surrounding rubber layer shall be more than 0.4mm.

Other auxiliary processes for silicone rubber products

A. Glue injection (including glue) process:Similar to injection molding, the parts to be injected are fixed first, and the first layer of mold is closed to control the raw materials not to pollute the parts not designed for injection.Then close the second layer of the mold, the plastic pressure molding.

B. Glue rolling process: manual preform the glue material into the mold first.This process can be used in the case of whole bread glue.

C. Rubber dipping: the raw material of the rubber (rubber) body is a fluid, and the workpiece is immersed in the raw material for many times.The inner material is cured and then soaked again.Until the design thickness is reached.

D. Glue drop: the raw material has good fluidity, which is similar to paint and vulcanized at room temperature.The mould is simpler and generally operated by hand in the first place.Apply a layer of fast curing paint next time

E. Multi-color products: A, 2 sets of molds for fractional vulcanization,B, manual color matching, and one-time vulcanization, requiring A certain height of color separation of parts.In order to avoid mixed color conductive adhesive bonding, secondary vulcanized silicone and silicone (rubber) can be done without direct vulcanization bonding