Plastic injection mold

Plastic injection molding, a cornerstone of modern manufacturing, revolutionizes the production process for a multitude of plastic components. This article delves into the production process of plastic injection molds, their extensive applications, and the numerous advantages they offer across industries.

Production Process of Plastic Injection Molds:

The production of plastic injection molds entails a precise and methodical approach. Here's an overview of the typical process:

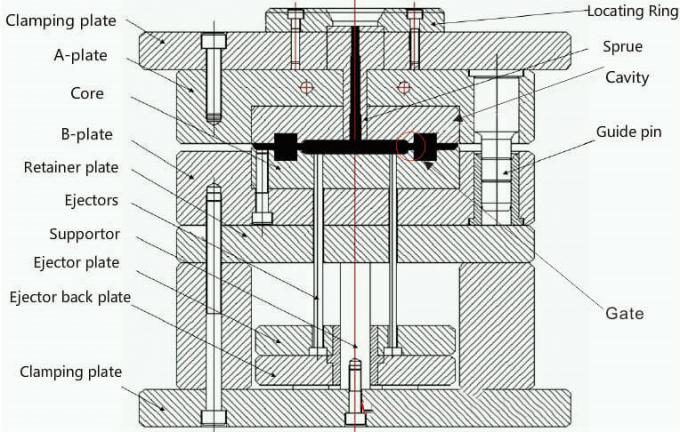

Design and Engineering: Engineers utilize CAD (Computer-Aided Design) software to meticulously design the mold, considering factors like part geometry, material selection, and cooling channels.

Mold Fabrication: Skilled machinists employ CNC (Computer Numerical Control) milling machines or EDM (Electrical Discharge Machining) equipment to fabricate the mold cavity and core with utmost precision.

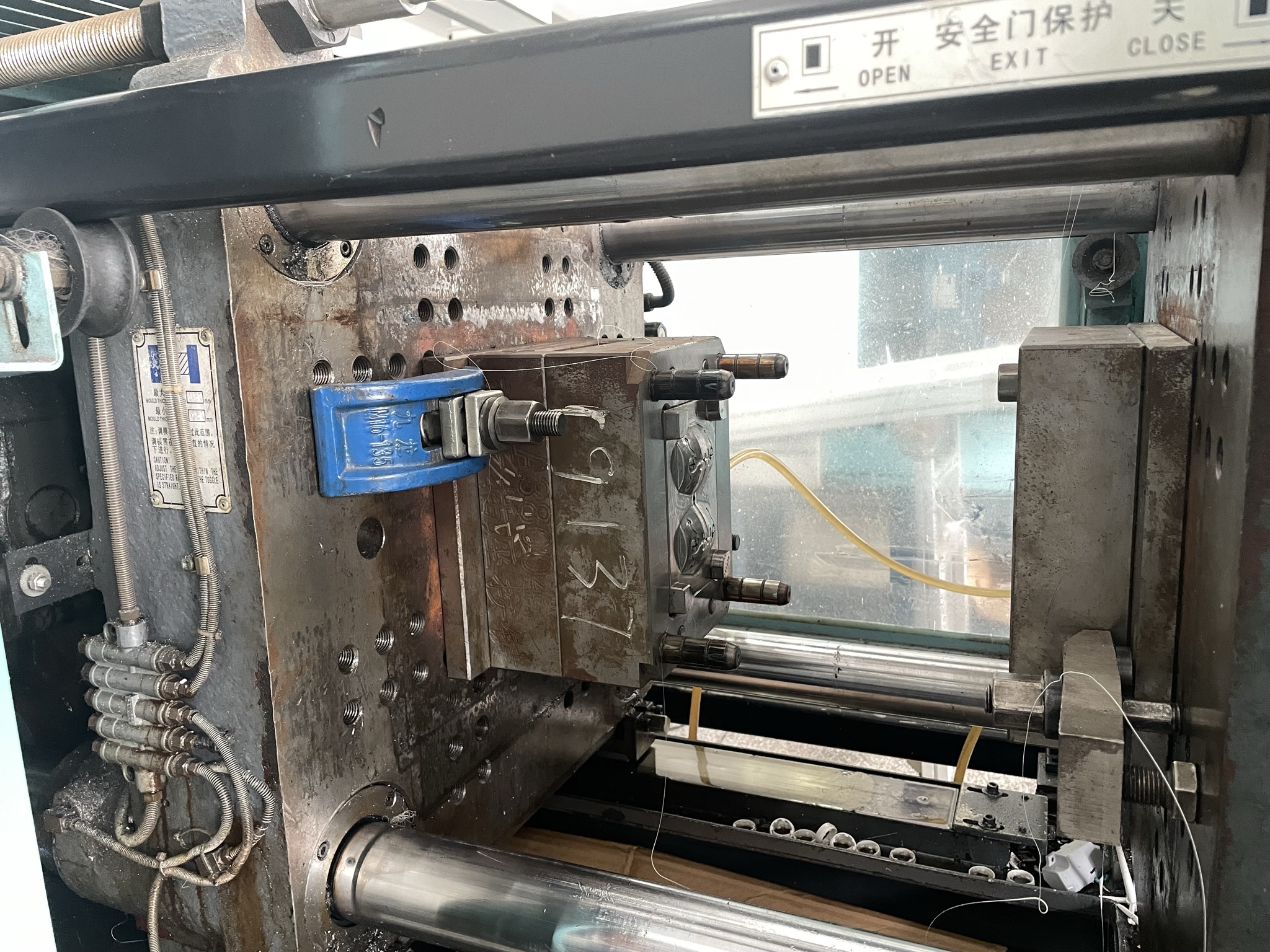

Injection Molding: The fabricated mold is mounted onto an injection molding machine. Molten plastic resin is injected into the mold cavity under high pressure, taking on the desired shape. After cooling, the molded part is ejected from the mold.

Finishing and Quality Control: Post-molding, parts may undergo trimming, deburring, or surface treatments. Stringent quality control measures ensure dimensional accuracy and mechanical properties.

Applications of Plastic Injection Molds:

Plastic injection molds find applications across diverse industries:

Consumer Products: From household items like containers and utensils to toys and packaging materials, plastic injection molds enable the mass production of consumer goods.

Electronics: Plastic molds produce casings, enclosures, and intricate components for electronic devices, ensuring precision and durability in products like smartphones, laptops, and appliances.

Automotive: Plastic injection molds manufacture interior and exterior components, contributing to lightweight, fuel-efficient vehicles with enhanced safety features.

Medical: In the medical sector, plastic injection molds are instrumental in producing medical devices, instruments, and equipment with biocompatible materials and stringent quality standards.

Advantages of Plastic Injection Molds:

Plastic injection molds offer several advantages:

Cost-Effectiveness: High-volume production at low costs per unit makes injection molding economically viable for mass production.

Precision and Consistency: Exceptional dimensional accuracy and repeatability ensure consistent quality across large production runs.

Complex Geometries: Injection molding allows for the creation of intricate parts with complex features, unattainable through other methods.

Material Versatility: A wide range of thermoplastics and thermosetting resins accommodate diverse application requirements.

In conclusion, plastic injection molds are indispensable in modern manufacturing, facilitating the production of a myriad of products with efficiency and precision. Their versatility, cost-effectiveness, and ability to create complex parts solidify their position as a cornerstone of industry innovation.