High Precision Silicone Handle Grip Mold

Provide Service: Rubber compression molding, Rubber to metal molding, Rubber extrusion molding and Custom rubber molding

Application: applied in Automobile, furniture, machinery, electronic, household, medical, etc

OEM/ODM: Available

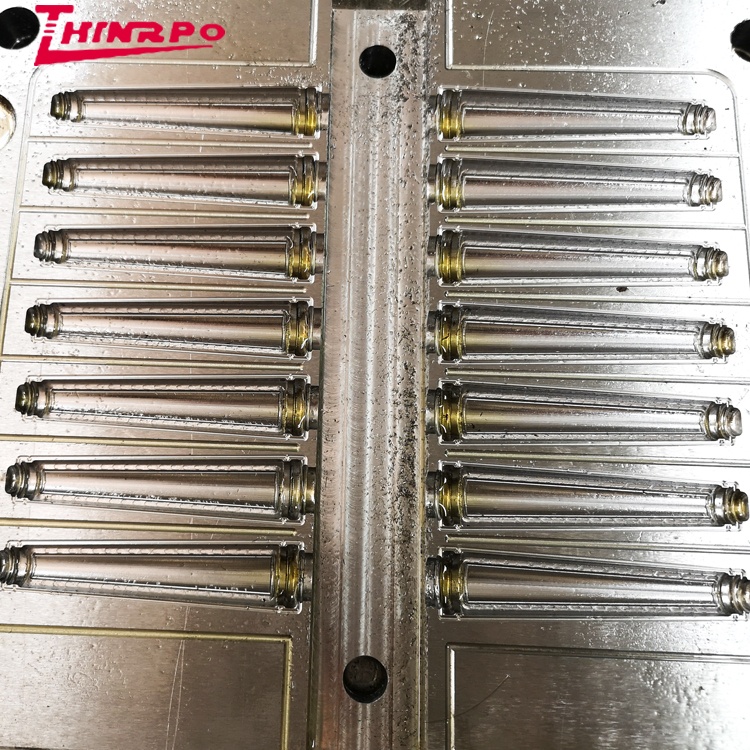

High precision silicone handle grip mold

Silicone Rubber Compression mold also known as compression molding, compression moulding, rubber mold, rubber mould, rubber molding, silicone rubber mold, rubber compression mold etc.

Compression molding is a widely used method in the processing of silicone rubber. It usually needs to be pre-formed according to the size and shape of the part, and then put into an open mold and vulcanized using a flat vulcanizer under a certain temperature and pressure.

There are several factors to be considered in the silicone rubber molding process:

One is the vulcanization amount of silicone rubber, that is, silicone rubber should be added with an appropriate proportion of double-two-five and platinum vulcanizing agent.

The second is the mold temperature. The mold temperature is determined according to the type of vulcanizing agent. If the temperature is too low or the vulcanization time is too long, the high temperature will make the silicone rubber embrittlement defect rate high.

Another factor is curing time, which is influenced by the first two factors. The more the vulcanizing agent is added, the higher the temperature, the shorter the vulcanization time. On the contrary, the less the vulcanizing agent is added, and the lower the vulcanization temperature is, the longer the vulcanization time is.

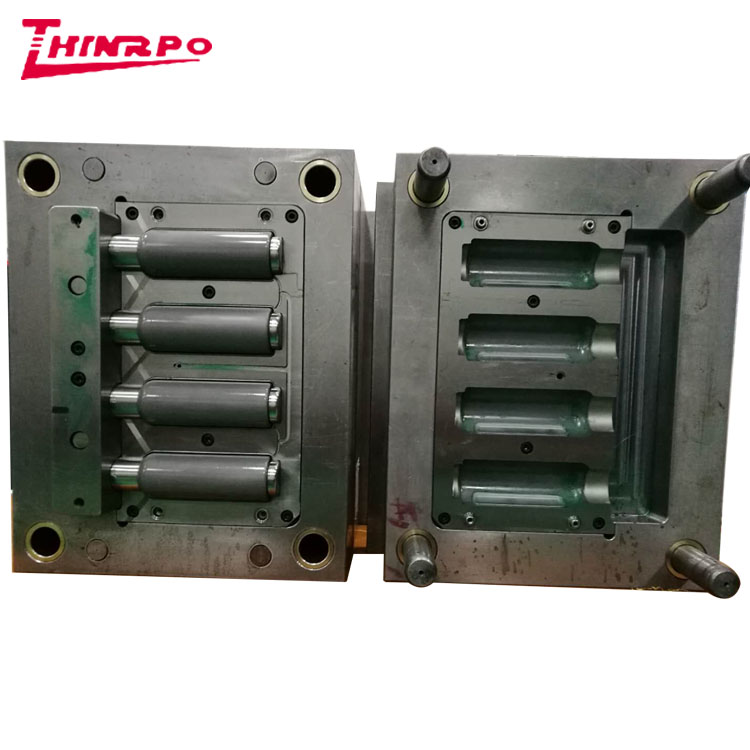

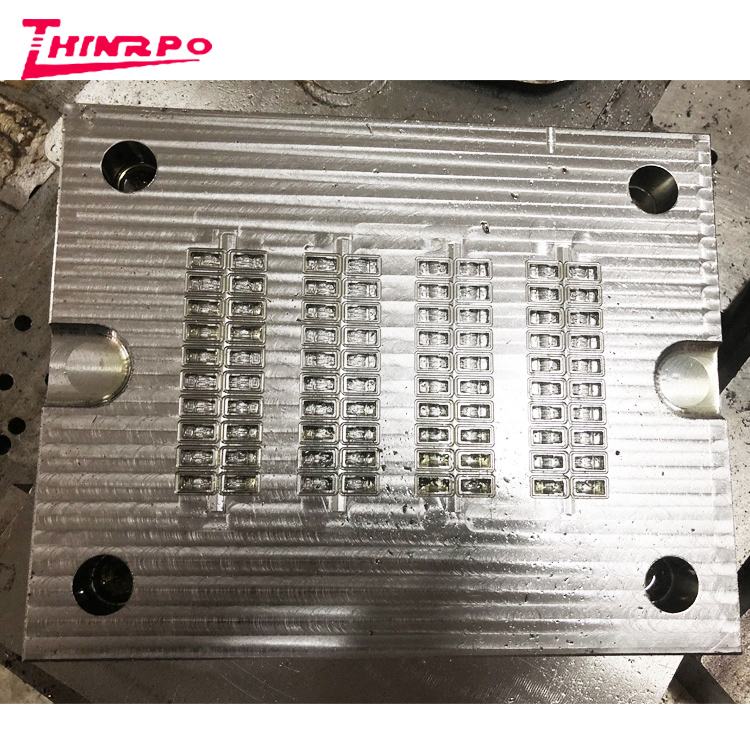

Rubber Mold Structure: generally divided into upper mold, lower mold, bottom plate, top plate, ejector pin, mold core, hinge and other auxiliary parts. We need to pay more attention to the characteristics of their molds and production processes.

Silicone grip also known as silicone handle, silicone grip, silicone handle sleeve, silicone handle grip, silicone handle cover, rubber handle, rubber grip, rubber handle grip etc.

Advantages:

Silicone handle is made of high quality silicone or rubber, non-toxic, soft, with good elasticity, good flexibility, good tear resistant, Anti-skid and wear-resistant, not easy to deform, good anti-skid shock absorption effect.

Application:

Sports equipment, handle for all kinds of tools and instruments, handle sleeve for toys, handle grip for baby carriage, grip for pet leash, handle cover for luggage.