Plastic two-shot mold

Plastic two-shot molding, also known as dual-shot or multi-shot molding, is a sophisticated injection molding process that enables the production of complex parts with two different materials or colors in a single operation. This innovative technique offers numerous advantages, making it a preferred choice for manufacturers across various industries.

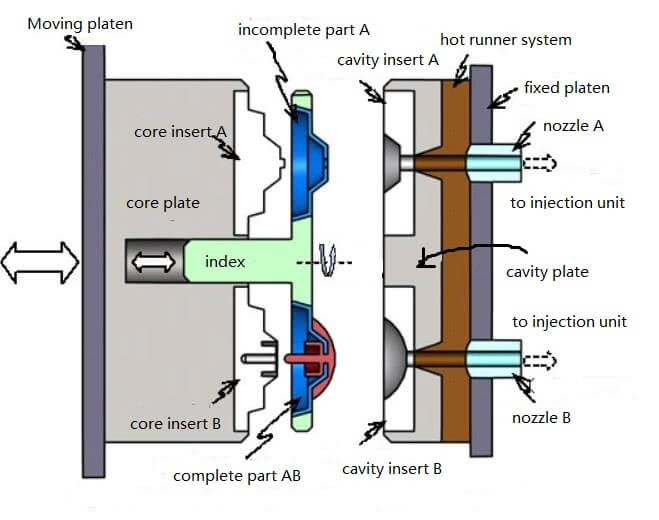

In two-shot molding, two different polymers or colors are sequentially injected into the same mold cavity, resulting in a part with distinct layers or sections. This process eliminates the need for secondary assembly operations, reducing production time and costs while improving part consistency and quality.

One of the primary benefits of two-shot molding is its ability to create intricate, multi-material parts with precise alignment and bonding between layers. This is particularly advantageous for applications requiring soft-touch grips, overmolded seals, or integrated gaskets in automotive, electronics, and consumer goods.

Additionally, two-shot molding allows for the combination of materials with different properties, such as rigid and flexible resins or clear and opaque polymers, in a single part. This versatility opens up new possibilities for product design and functionality, enabling manufacturers to meet evolving customer demands and market trends.

Moreover, two-shot molding enhances product aesthetics by enabling the integration of multiple colors or textures within the same part. This is especially beneficial for consumer products, where visual appeal plays a crucial role in brand differentiation and consumer preference.

Another advantage of two-shot molding is improved part durability and performance. By encapsulating or reinforcing critical components with a different material, manufacturers can enhance structural integrity, impact resistance, and chemical compatibility, prolonging the lifespan of the finished product.

Furthermore, two-shot molding offers environmental benefits by reducing material waste and energy consumption compared to traditional manufacturing processes. The ability to combine multiple functions or features into a single part also minimizes the need for additional components, further streamlining production and reducing overall material usage.

In conclusion, plastic two-shot molding represents a significant advancement in injection molding technology, offering unparalleled versatility, efficiency, and quality in the production of complex parts. With its ability to create multi-material, multi-color components with precise alignment and performance, two-shot molding is driving innovation and shaping the future of manufacturing across diverse industries.