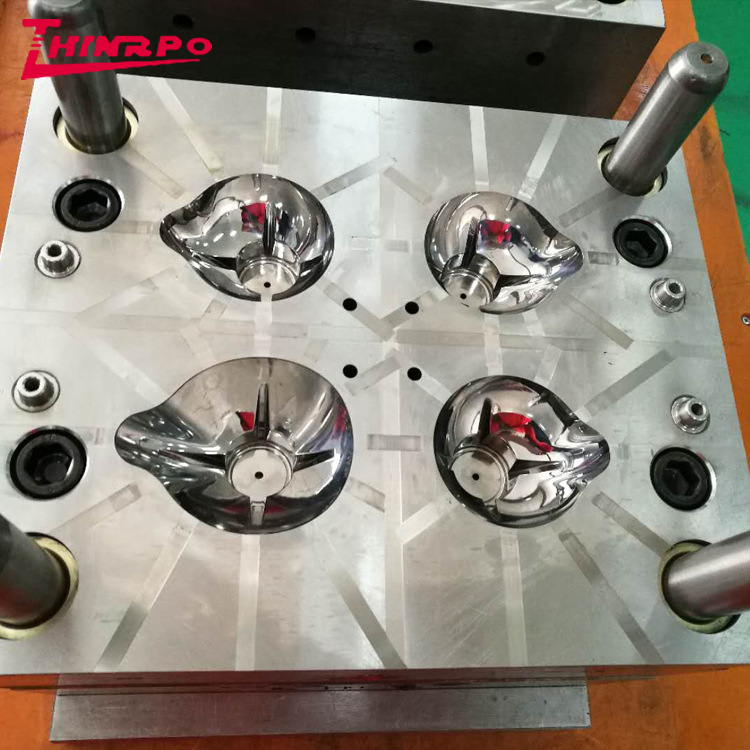

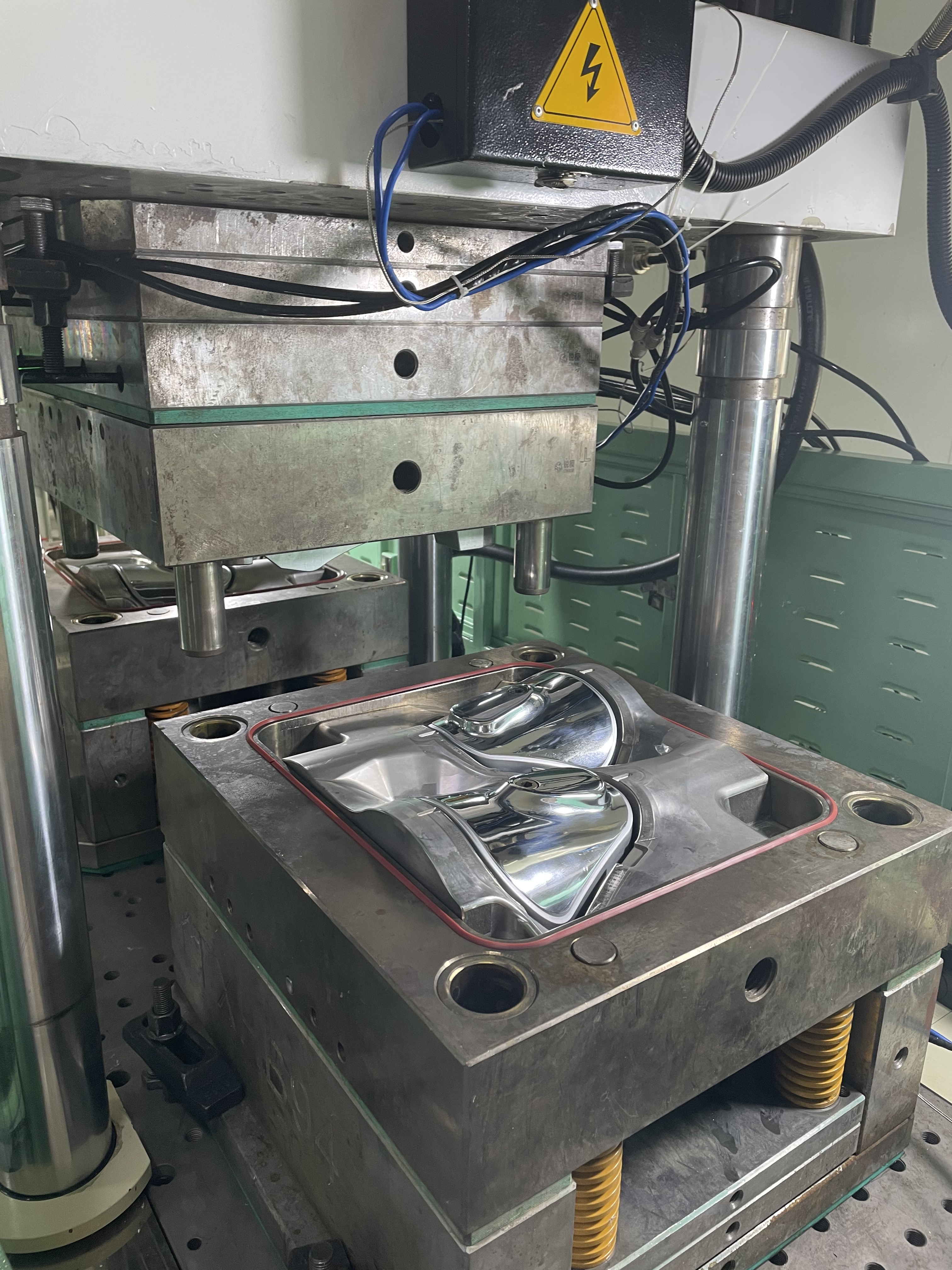

Liquid Silicone Rubber LSR Injection CPAP Full Face Mask Mould

Liquid silicone rubber molding, also known as LSR injection mould, is the use of liquid silicone rubber injection molding machine to produce liquid silicone rubber gaskets, seals, accessories or products.

Instead of using traditional silicone rubber compressors and traditional production methods, LSR injection moulds are used for production. Compared with rubber compression moulds, LSR injection moulds are safer, more precise, environmentally friendly, transparent, with less manpower and higher production efficiency.

Liquid silicone rubber LSR injection CPAP full face mask mould

LSR injection CPAP full face mask mould, is also called Liquid silicone rubber injection mold, LSR mask mold , which is widely use for producing medical or food grade high precision liquid silicone rubber parts by injection machines.

Liquid silicone rubber mask mold’s Feature:

Liquid silicone rubber mask mold , with excellent fluidity, good operability, no deformation, high temperature resistance, acid and alkali resistance, no expansion, good tension, tear, good crack strength, more times of mold turning, can be used repeatedly, suitable for precision small or complex patterns of small products. And easy to demoulding, shrinkage up to two parts per thousand.

Different from the way of molding:

liquid silicone rubber is injection molding liquid silicone rubber: national injection molding liquid silicone rubber, curing equipment for injection molding machine. The injection molding machine has the advantages of simple process, high precision, high output, manpower saving, electricity saving and material saving. It can produce all kinds of high temperature rubber products and is the mainstream of silicone rubber material development in the future.

Solid silicone molding is a kind of solid raw material. After mixing with the blender, the cutting machine cuts into products and molds of appropriate size and thickness, which are then placed into a mold, pressure forming machine and molded at a certain temperature. When demoulding and plastic products at the same time, also need to clean the mold and so on.

Different from the mold structure:

the structure of the solid silicone mold is generally simple, and it only needs to be processed into the corresponding cavity and cavity according to the parameters of the product, and the processing cost is relatively low.

The structure of liquid silicone rubber mold is complex, and it is necessary to consider the location of the injection port, the design of the cold runner system, the design of the exhaust system, the temperature monitoring of the mold and other problems, and the mold processing cost is high.